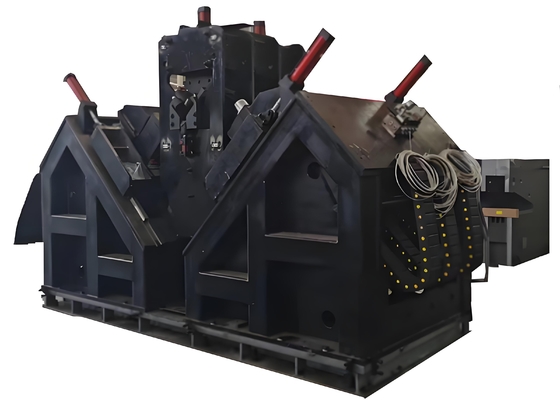

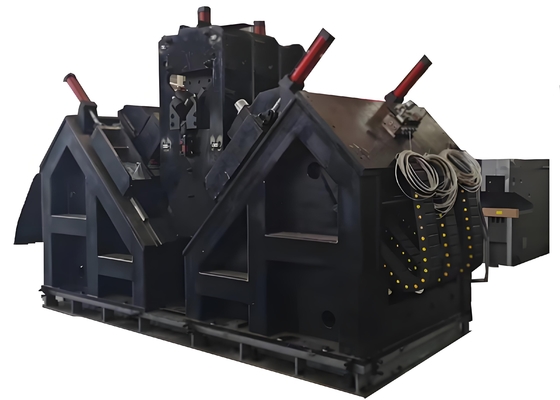

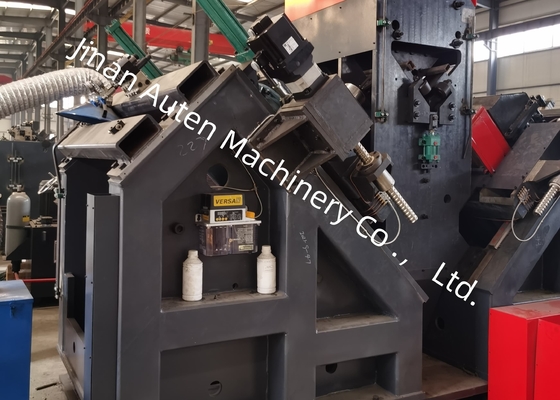

Линия сверления и нарезания резьбы на уголках с ЧПУ, по 3 сверла с каждой стороны, скорость подачи 40 м/мин

Применение продукта:

Эта производственная линия специально разработана для сверления и штамповки крупногабаритного высокопрочного углового профиля, применяемого в башнях линий электропередач. На этой линии можно обработать все необходимые отверстия в угловом профиле, обеспечивая отличное качество отверстий, высокую точность позиционирования, а также высокую производительность и передовые возможности автоматизации.

Основные параметры:

| Модель |

ADM2532 |

| Размер уголка (мм) |

140*140*10~250*250*32 |

| Макс. длина сырья (м) |

14 |

| Усилие маркировки (кН) |

1000 |

| Кол-во групп символов |

1 |

| Кол-во символов |

18 |

| Размер символов (мм) |

14*10*19 |

| Диапазон точного расстояния (мм) |

50~220 (Бесступенчатый) |

| Кол-во сверл с каждой стороны |

3 (2 группы, всего 6) |

| Кол-во лезвий с каждой стороны |

3 |

|

Конус сверлильного шпинделя

|

BT40 |

| Макс. диаметр сверления (мм) |

Φ40 |

| Макс. скорость вращения шпинделя (об/мин) |

6000 |

| Блок охлаждения сверла |

MQL 360-2 (Сухое охлаждение) |

| Объем хранения масла в блоке охлаждения |

2 л |

| Смазочно-охлаждающая жидкость |

Микро-смазочно-охлаждающие жидкости на растительной основе (2000-25) |

| Расход топлива |

5~50 мл/ч |

| Тип привода тележки ЧПУ |

Серводвигатель переменного тока, реечная передача |

| Макс. скорость подачи уголка (м/мин) |

40 |

| Метод привода перемещения по оси AB |

Линейная направляющая; серводвигатель переменного тока; шарико-винтовая передача, вторичный привод |

| Макс. скорость перемещения каретки сверлильной головки (м/мин) |

10 |

| Тип привода сверлильной головки |

Линейная направляющая; серводвигатель переменного тока; шарико-винтовая передача, вторичный привод |

| Макс. скорость подачи сверлильной головки (м/мин) |

14 |

| Метод работы руки подающего устройства |

Вертикальный подъем |

| Количество опрокидывающих цилиндров на стороне выгрузки |

4 |

| Метод охлаждения гидравлической станции |

Воздушное охлаждение |

| Кол-во осей ЧПУ |

9 |

| Давление воздуха (МПа) |

1 |

| Общая мощность |

Около 150 кВт |

Особенности продукта:

1. Сверлильный шпиндель оснащен механизмом автоматического зажима инструмента с дисковой пружиной и гидроцилиндром для освобождения инструмента, что обеспечивает удобную замену хвостовиков инструмента. Передняя часть шпинделя имеет лабиринтную уплотнительную защитную конструкцию и водонепроницаемую конструкцию, а также оснащена устройством воздушной завесы — эта конфигурация эффективно предотвращает попадание охлаждающей жидкости внутрь шпинделя.

2. Производственная линия оснащена устройством автоматической загрузки (включающим поперечный канал подачи и вращающуюся загрузочную стойку), устройством автоматической выгрузки и устройством автоматической подачи. Все отверстия и идентификационные метки на угловом профиле могут быть выполнены за один проход через производственную линию, без необходимости ручного вмешательства в процессе обработки. Это не только упрощает рабочий процесс, но и значительно снижает трудоемкость операторов.

3. Маркировочный блок имеет закрытую конструкцию корпуса, отличающуюся высокой прочностью конструкции и стабильной работой. Он оснащен опорой станины (закрепленной на основании станка), подвижной станиной и гидравлическим прессовым блоком символов. В соответствии с инструкциями компьютера операции маркировки выполняются в положениях, указанных в инженерных чертежах. Для расширения диапазона обработки станка дополнительно интегрирован механизм ручной регулировки. Этот механизм позволяет регулировать положение подвижной станины (т. е. положение головки символа), обеспечивая адаптацию к положениям маркировки углового профиля с различными спецификациями.

Эти образцы охватывают различные распространенные спецификации и компоновки отверстий углового профиля, применяемого в башнях линий электропередач. Они позволяют потенциальным пользователям или инспекторам визуально проверить эксплуатационные характеристики оборудования, тем самым предоставляя ощутимые и интуитивно понятные ссылки для оценки соответствия оборудования практическим требованиям производства.

Это оборудование специально разработано для сверления и штамповки крупногабаритного высокопрочного углового профиля, используемого в башнях линий электропередач, и широко применяется в различных сценариях при строительстве и обслуживании инфраструктуры передачи электроэнергии. При строительстве линий электропередач сверхвысокого напряжения (СВН), где башни должны выдерживать экстремальные погодные условия и большие нагрузки, это оборудование играет решающую роль в обработке компонентов углового профиля, составляющих основную раму башен. Оно эффективно выполняет задачи сверления и штамповки для углового профиля, используемого в корпусах башен, траверсах и других ключевых конструктивных частях, гарантируя точную размерную точность и прочные соединения для обеспечения общей устойчивости башен.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!